YP W500

Robust 5-Axis Dental Milling Machine

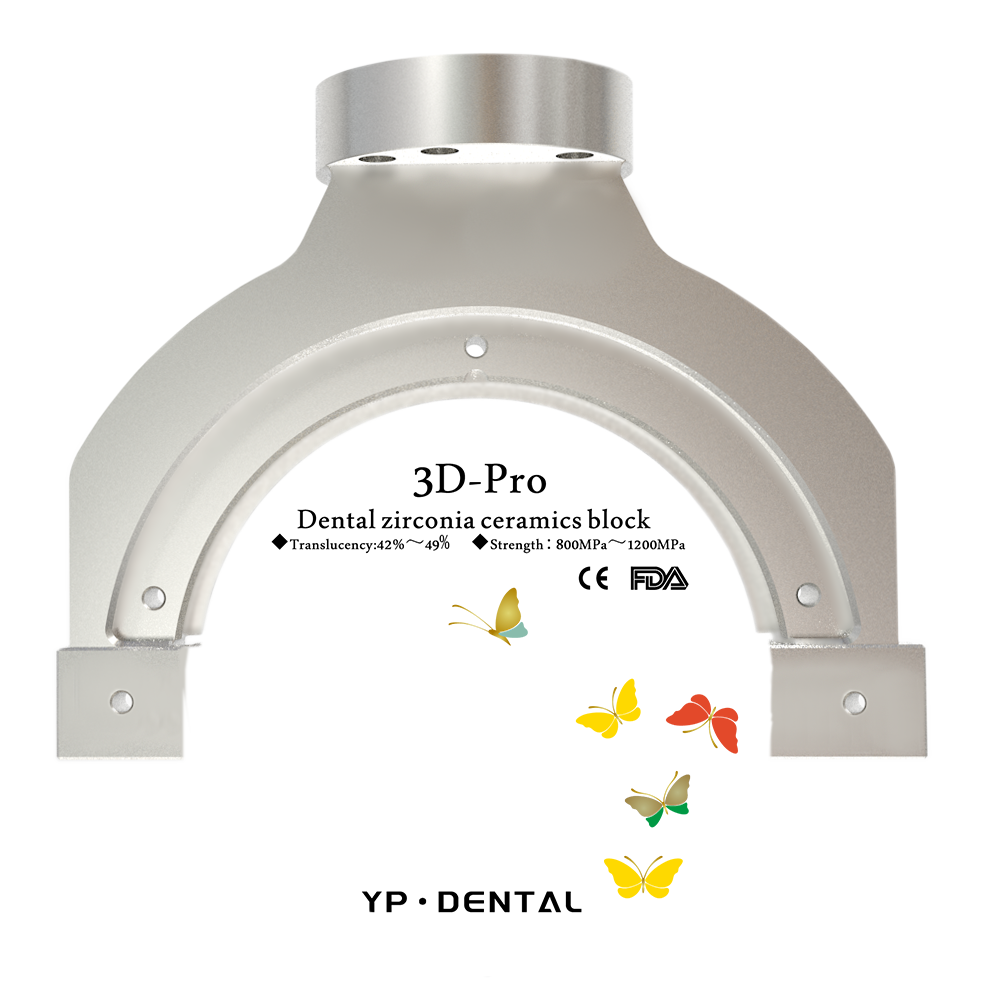

YP W500 is a 5-axis wet-milling machine for dental CAD/CAM systems, featuring high efficiency, high reliability and intelligent processing. Equipped with over 15 milling burs, a premium spindle, a high-precision servo motor control system, and an intelligent touchscreen, it serves as a powerful assistant for metal processing. With its robust and reliable structural design and a repetition accuracy of ±0.005mm, the YP W500 makes the processing of customized abutments, screw-retained bridges, and implant bars simple and reliable.

5

Axis

Dry & Wet

Milling

2.5kW & 62mm

Occlusion

± 0.005 mm

Accuracy

90°

Milling

15

Milling burs

lt’s your first choice

Why YP W500?

All in one

W500 can mill titanium disc, premilled abutment, glass ceramic, zirconia and more

Powerful

Powerful performance.

62mm&2.5kW spindle

Efficient

Premilled abutment: 15min, glass ceramic: 20min,

screw-retained bridge: 4.5h

Automatic hiding design for tool library

Protecting the tool library and tool setter from debris and liquid contamination greatly reduces equipment failure rates.

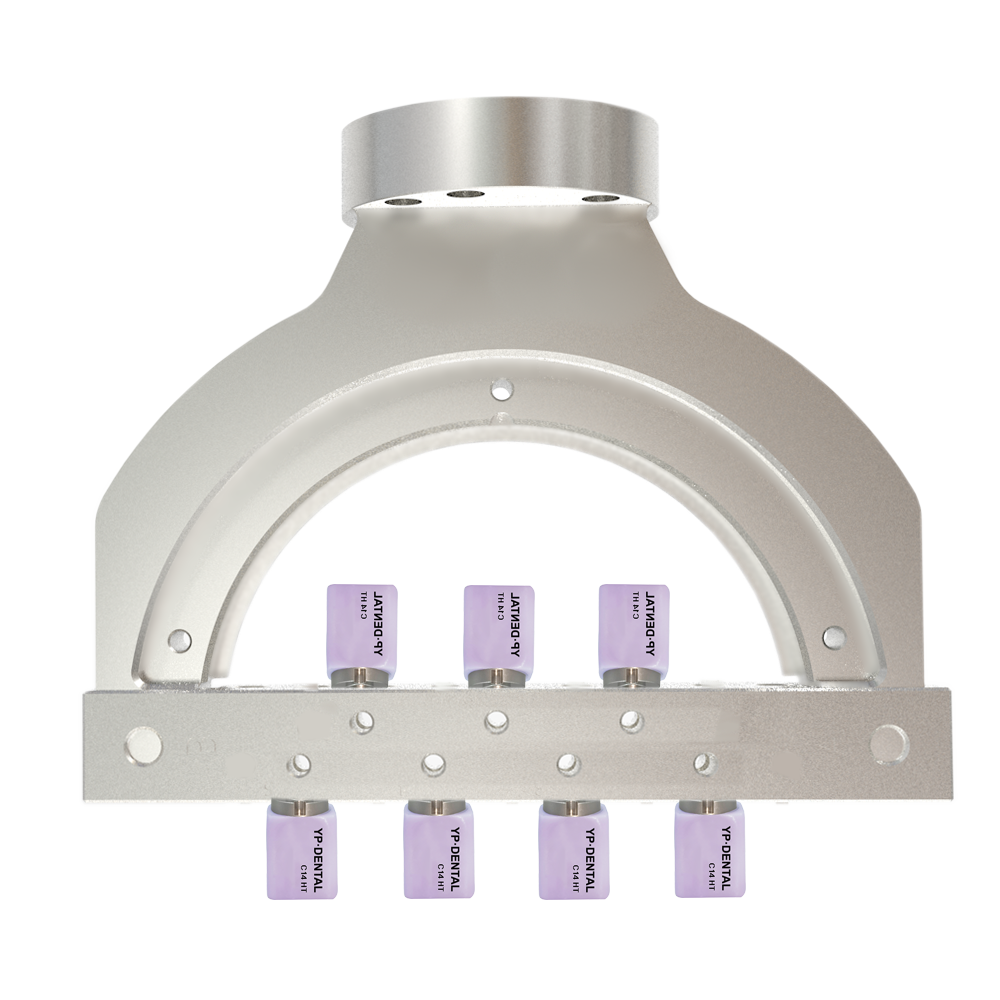

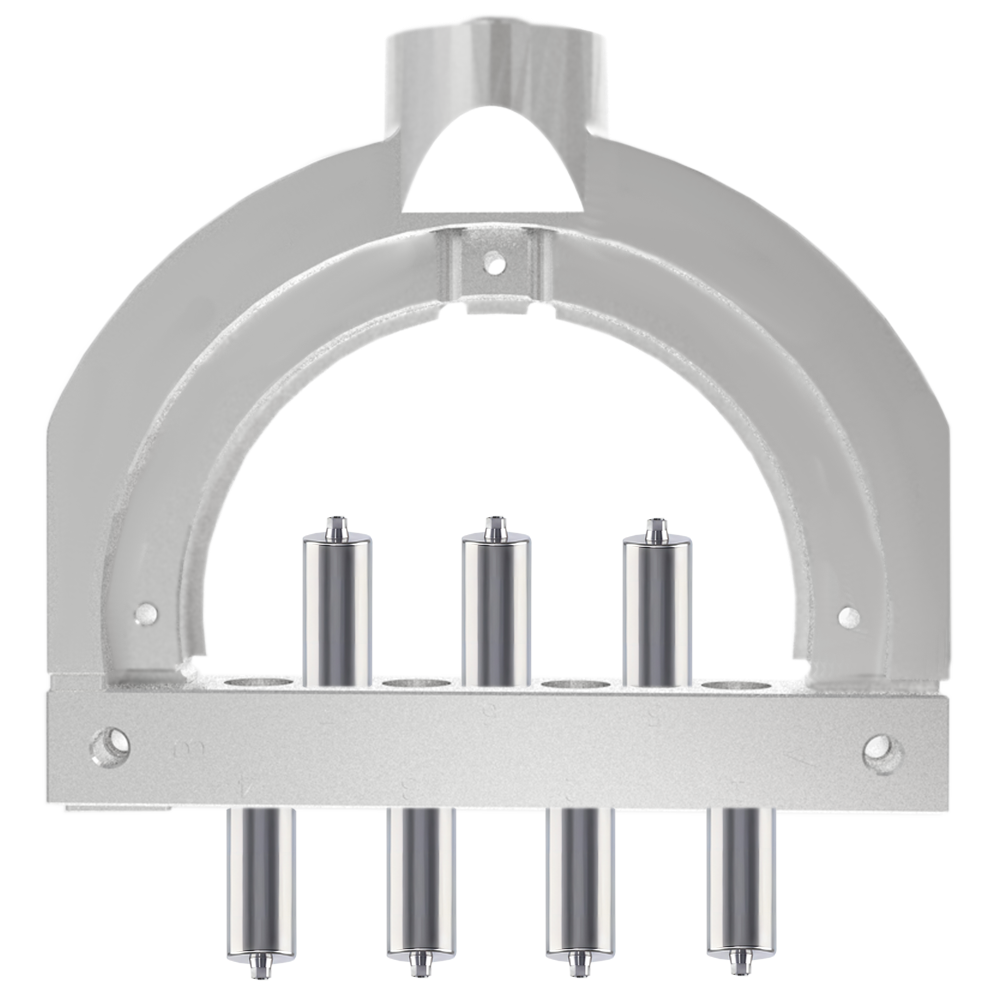

Large capacity fixture

9 glass ceramics or 7 premilled abutments can be milled at one time

Large B-axis rotation angle

B axis: -120°~+30° which can process large-angle implants

Dry & Wet

Processing modes

The three types of fixtures can be easily switched to meet the processing needs of different materials.

Crown / Bridge

Inlay / Onlay

Abutment

Vaneer

Model Cast

Denture

Occlusal Splint

Screw-retained Bridge

Surgical Guide

Implant Bur

Glass Ceramic

Pre-mill Blank

Titanium Disc

Titanium Alloy Disc

COCR

PEEK

PMMA

Zirconia

Wax

| Device Name | YP W500 |

|---|---|

| Processing mode | Dry or Wet |

| Processing material | Zirconia, Glass ceramic, PEEK, Titanium, CoCr |

| Power | 220V / 3.2kW |

| Application | Crown | Bridge | Veneer | Inlay | Onlay | Abutment | Denture | Screw-retained bridge | Model cast | Occlusal splint | Surgical guide | Implant bar |

| Size | 820*660*650 (mm) |

| Weight | 200kg |

| Air pressure | >0.5MPa |

| Air flow | >90L/min |

| Water tank capacity | 30L |

| Basic construction | Aluminium & Steel |

| Number of axis | 5 |

| Rotation axis angle | A axis: -120°~+30°,B axis: 360° |

| Tool number | 15 |

| Tool diameter | 6mm |

| Spindle speed | 60000rpm |

| Spindle power | 2.5kW |

| Spindle diameter | 62m |

| Processing accuracy | Position: 0.01mm,Repeated : 0.005mm |

| Spindle Cooling Method | Water cooling |

| Clamps | C-clamp,Block holder,Premill abutment holder |

| CAM software | WorkNC |

YP W500 is a 5-axis wet-milling machine for dental CAD/CAM systems,

featuring high efficiency, high reliability and intelligent processing.

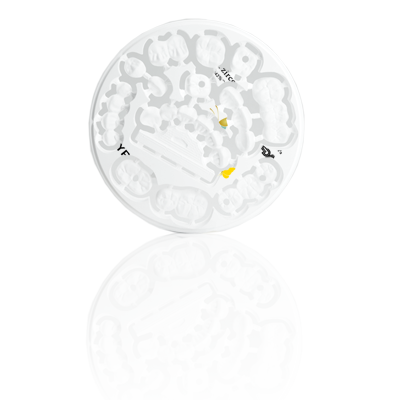

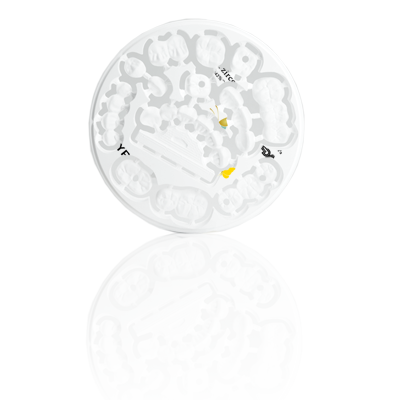

98mm C-clamp

9 positions glass ceramic holder

7 positions pre-mill abutment holder

| Metal (10) | Glass Ceramic (3) | |

|---|---|---|

| T1_Ball end R1.5*14L*6D*50L |

T6_Flat end D2.0*5L*6D*50L |

T12_Ball end R1.25*16L*6D*50L |

| T2_Ball end R1.0*12L*6D*50L |

T7_Flat end D1.0*5L*6D*50L |

T13_Ball end R0.5*10L*6D*50L |

| T3_Ball end R0.5*12L*6D*50L |

T8_Ball end R0.75*13L*6D*50L |

T14_Ball end R0.3*16L*6D*50L |

| T4_Bull nose end D2.0*R0.2*14L*6D*50L |

T9_Drill D1.5*8L*6D*50L |

|

| T5_Bull nose end D1.5*R0.1*14L*6D*50L |

T10_Drill D2.2*16L*6D*50L |

CONTACT YPDENTAL

Questions or Need Help? we provide 7*24 service. Please contact us if you need.