High-quality adsorption

denture solution

YP Resin-base Injector

YP. Injector consists of an injection unit, injection bottle and accessories.

It realizes fully automated operation through digital devices and precise temperature control through electric heating, which eliminates steam pollution during traditional processing and allows the base to fully polymerize, making it simple and fast.

2

Flask

Electiric Heating

6.5

Bur

0

Steam

Outstanding Advantages

Fully Automatic

- One-button operation,

- Three sets of heating programs.

Low cost, new gypsum embedding process

- The rubber holder has no waste edges,

- The surface is smooth and easy to polish,

- The adsorption force is stronger.

High Efficiency

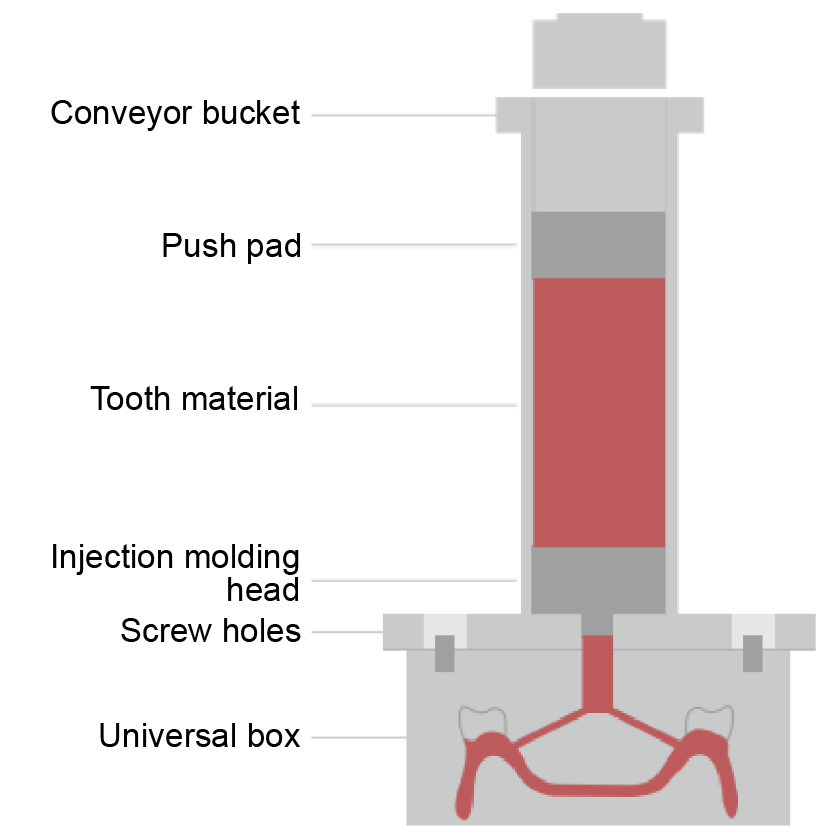

- Automatic injection molding,

- Two mold boxes can be processed at one time.

Low Cost

- Compared with traditional manual injection, YP injector saves more than 50% of material consumption.

High-Precision

- Continuous pressure injection molding,

- Precise shrinkage compensation.

Safety Door

- Equipped with safety door to ensure safety and visualization during operation.

Continuous pressure compensation, zero deformation, tighter

The polymerization shrinkage of the resin can be completely compensated by the subsequent resin pressed in. In this continuous cycle, the shrinkage of the denture will eventually approach zero infinitely. Provides a precise fit of the restoration and an excellent, smooth surface.

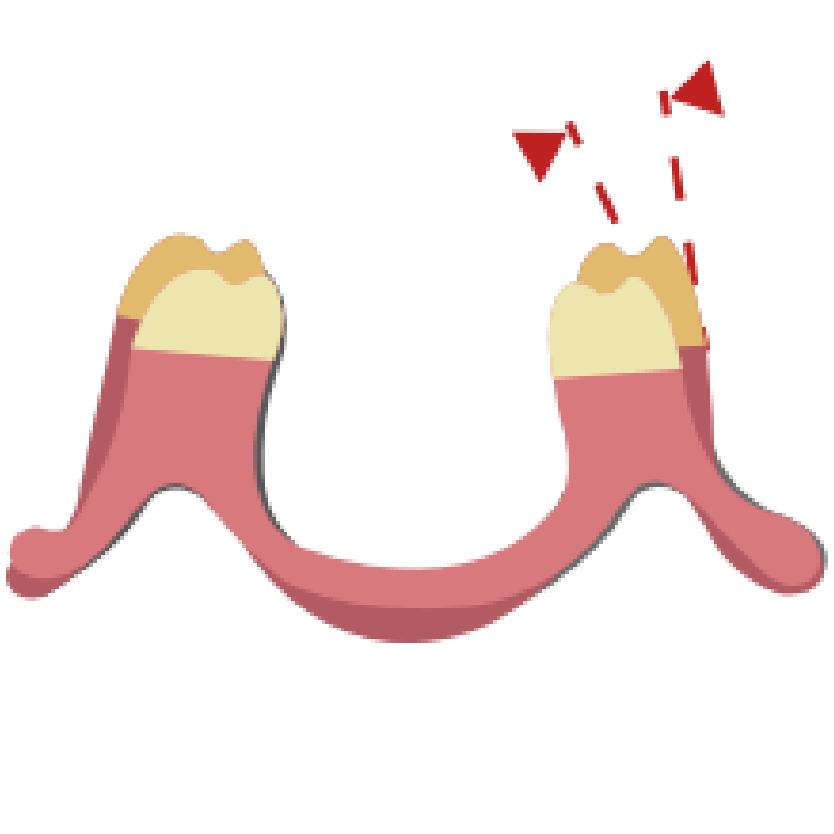

Improve the degree of polymerization of the base, and the bonding force between the resin teeth and the base will be stronger

High-pressure thermal polymerization can not only form a high degree of polymerization of the base, but also create a better bonding effect between the resin tooth and the base.

The thermally cured monomer reacts deeply and diffuses to the bottom of the resin tooth to form a stronger bond.

Traditional cold-cured denture base materials

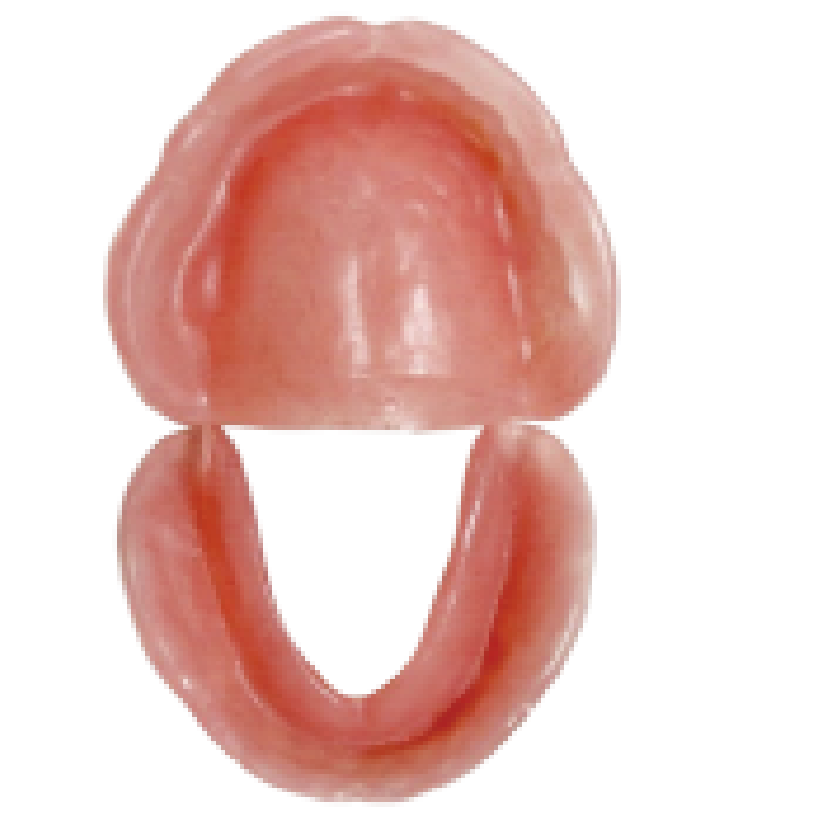

The plastic holder has high density, smooth surface, tight

The thermally cured monomer reacts deeply and diffuses to the bottom of the resin tooth to form a stronger bond.edges and stronger adsorption force.

Controlled polymerization prevents the vertical dimensions of the base from increasing and deforming. Reduce unnecessary subsequent manual grinding and adjustment processes.

The high-pressure glue injection continuously compensates, and the rear bank area has no shrinkage and deformation, is tighter and more closed, and improves the adsorption capacity of the glue holder.

For patients

- Zero deformation, comfortable fit

- Smooth surface to reduce plaque

- Low monomer residue and non-allergenic

For doctors

- The best solution for every type of patient

- High quality, no rework, reducing after-sales problems

For factory

- Save manpower and technology dependence

- Fully automatic operation, time-saving and efficient

- High quality and more stable

PRODUCT INFORMATION

Model

Voltage

Working Current

Power

Maximum Temperature

Weight

Dimensions(Mm)

Pressure

YP. injector

220V

3.9A(MAX)

850W(MAX)

110C

23.5Kg

300*400*500

0.6~0.8Mpa

Resource

Download and Contact

CONTACT YPDENTAL

Questions or Need Help? we provide 7*24 service. Please contact us if you need.